Before I can finish painting the cover, the latch that holds it closed needs to be worked out. I have the original, but it is in sad shape. Whatever broke the original cover, bent the latch assembly as well. The other problem is that I don't have the nice "Y" in the middle of the part to place the latch handle, so if I used the original, it would cover up some of my letters. Also, the catch that attaches to the cover no longer fits due to the letters on my new cover.

I could modify the original, but I have a hard time hacking up a piece that is 90 years old. So I decided to design up my own latch assembly based on the original. Here's what it looks like. You can see that the handle does not cover up the letters.

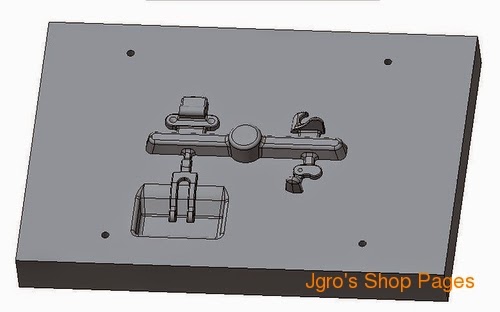

I decided to make a match plate pattern due to the small size of the parts and the parting line steps that the parts would need. It is much easier than trying to carve out the sand to achieve this. Here is the pattern in CAD.

I am going to eventually cast this in brass, but for now I'm going to make them from aluminum and try my hand at polishing the parts. I'm not set up yet to do brass/bronze, so it could be a while before I can do this. I decided to use my new aluminum flask for this project. Here are the CNC'd patterns in the flask before I rammed in the sand.

The patterns pulled clean except for one little piece that broke out on the catch. That just means more sanding. No big deal.

All ready to pour along with some other parts.

They turned out pretty good. The surface finish is a little rougher that I would like, but they are getting sanded/polished anyway. I'm pretty happy with them. The heavy flash line is from the pattern. I used a 1/8" ball end mill to cut the patterns which left a 1/16" radius where the part meets the flat surface of the match plate.

No comments:

Post a Comment

Note: Only a member of this blog may post a comment.